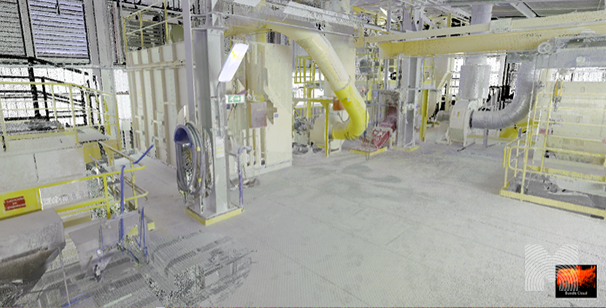

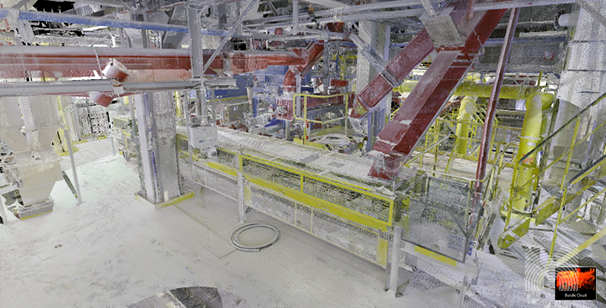

3D MEASURING FOR ASSET MANAGEMENT IN FACTORIES

Many factories grow organically. Meaning that a factory was built 50 years ago and over the years new and different machines have been added. Often this is not clear and certainly not documented in 3D. This makes the process of fitting new equipment over the years more complicated as the factories become increasingly full. Without a clear as-built situation, it is sometimes impossible to place new machines. This is where 3D measurement provides the solution. By having a clear 3D as-built situation, new machines can be fitted into the design without the need for the designers to be on site.

Apart from an enormous amount of travelling time, this also saves a lot of headaches at the front and back end of the process. At least as important is to check whether the machine can be placed on location. An often occurring phenomenon when placing new machines is that the machine fits on the designated location, but cannot be placed there because the road to it is too narrow. This is also a thing of the past with 3D measurement. Here it is possible to see beforehand and without being on location how the machine can be placed at the desired location, and if necessary to come up with a plan to dismantle certain machines to clear the way for the new machine.